Webinar: Navigating the ISA/IEC 62443 Standards

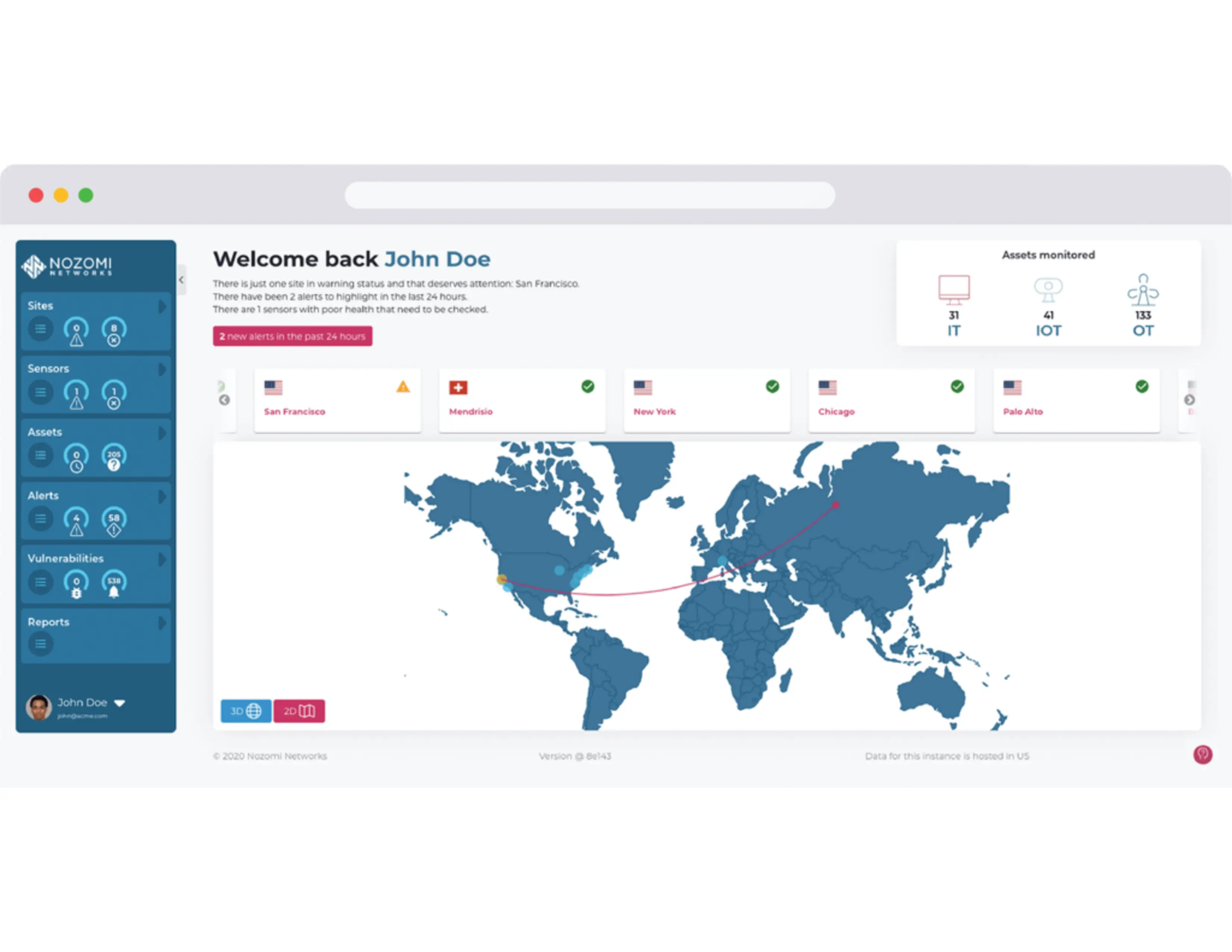

Save My SpotNetwork monitoring is the process of capturing network traffic data, usually via a SPAN port or network TAP in industrial environments, to analyze it for security and operational anomalies. A good network monitoring solution offers a comprehensive network topology map with actionable security and operational insights from the data.

To spot and troubleshoot networking and communication issues that threaten both cybersecurity and reliability, you need real-time visibility into your assets, connections, communications, protocols and more.

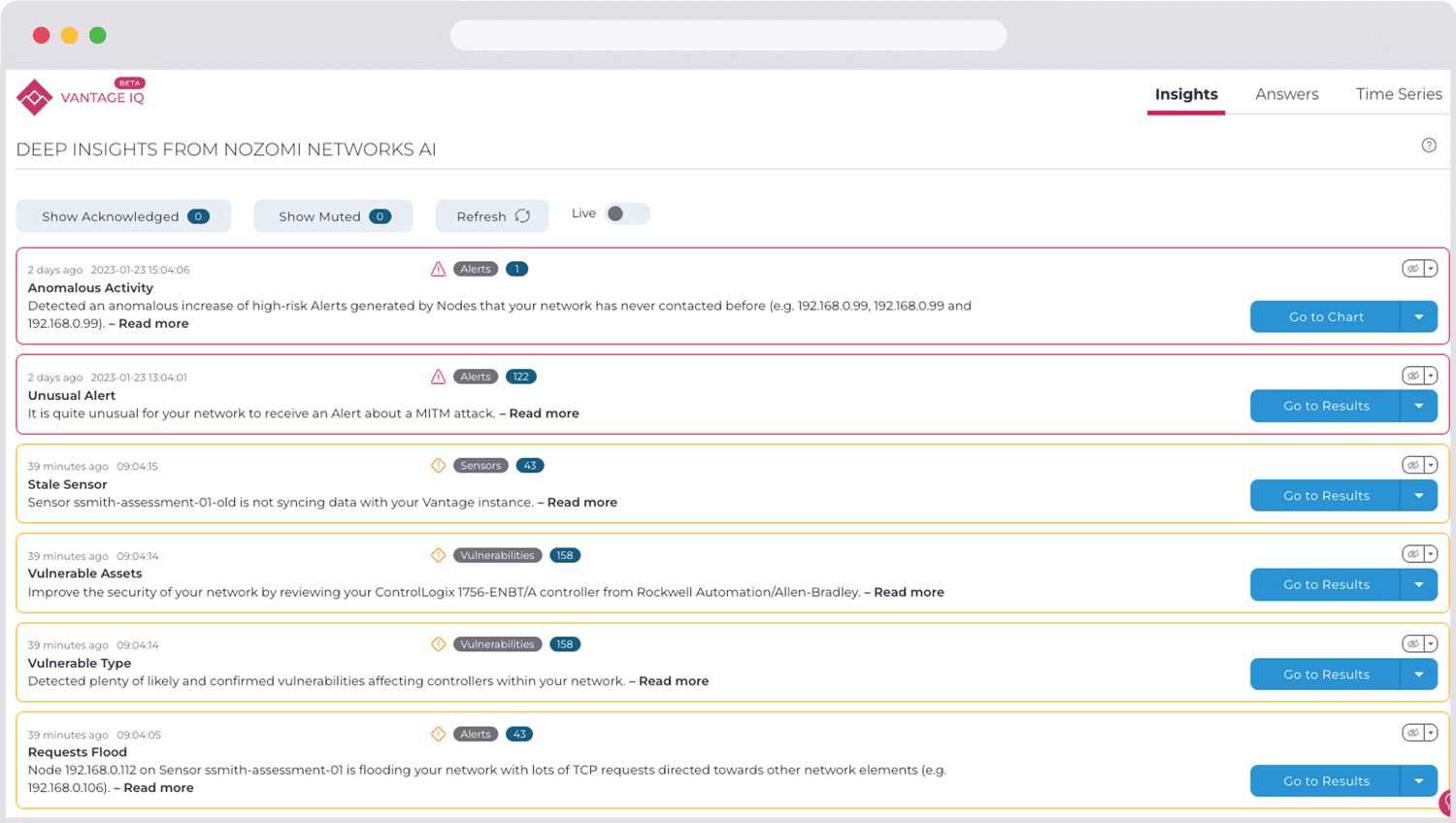

Pinpoint the cyber and operational anomalies that matter most

Access AI-powered insights to prevent anomalies from impacting operations

Continuously monitor your assets and networks for changes

Scale OT network monitoring across multiple plants, sites and teams

Our comprehensive deep packet inspection covers a wide range of industrial, IoT and IT protocols.

Learn more

Quickly uncover and prioritize the risks that matter to keep your systems reliable and secure.

Learn How

Dashboards, query capabilities, playbooks and forensic tools to help coordinate remediation efforts across teams.

View Demo